Patented Sunpower Maxeon IBC N-Type Technology

IBC . base plate technology

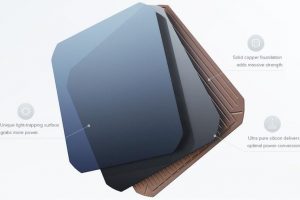

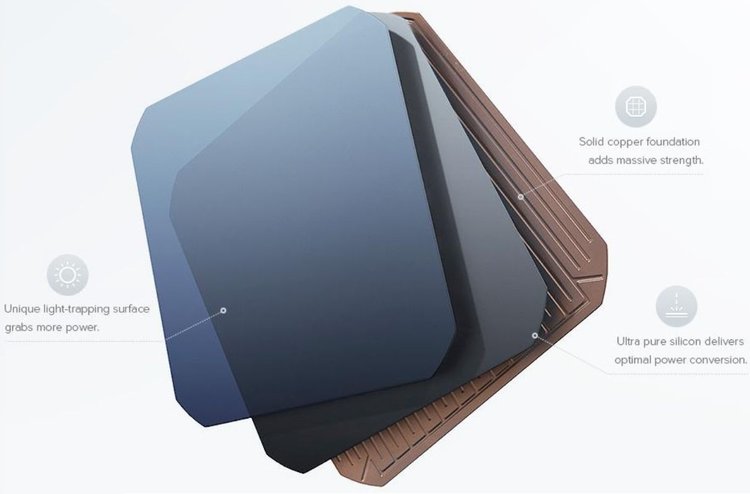

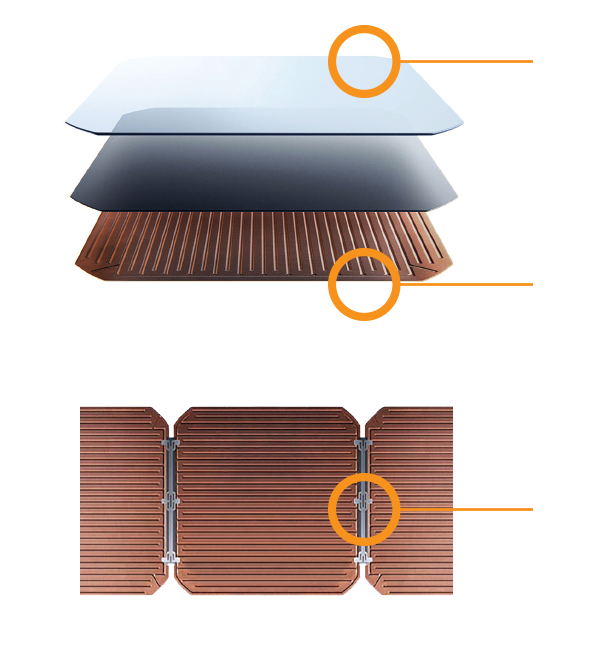

Common panels usually have 4 to 6 busbar bands and many small electrical lines (fingerprints) on the cell surface, these structures block part of the light absorbed into the cell. Technology IBC, abbreviation from English is “Interdigitated Back Contact”, there are many current guides (over 30 conductors) interwoven together on the underside of the Cell, the top of the battery cell is completely removed. The obstacles caused by the busbar and the tiny “fingerprint” electrical path, make the battery cell look better, more efficient and more durable.

Sunpower used a full sheet high-grade copper alloy IBC layer on Maxeon battery cells, this technological solution has been patented. With a conductive panel like a highly reflective metal mirror layer, which reflects any light radiation that passes through the Cell layer back into the Cell, significantly improving performance. This Sunpower IBC layer also helps strengthen the Cell to help it withstand stress, can be bent, not brittle like other conventional panels.

Sunpower’s IBC technology makes Cell more resistant to stress and more durable

Công nghệ cell pin N-Type

A solar cell is a silicon crystalline wafer coated with various chemicals to generate electricity. The basic difference between P-type and N-type battery cells is in the chemical coating on the cell surface, resulting in a different number of electrons. With the P-Type cell, the chemical that coats the silicon wafer is boron, which has fewer electrons than silicon, so the cell has a positive charge, while the N-Type chemical that coats the wafer is phosphorus, which carries more electrons than silicon, so it charges. minus.

The first battery cell successfully manufactured by Bell Laboratories in 1954 was the N-Type back contact type. However, at that time, solar was mainly used for aerospace science and P-type battery cells were better able to withstand space radiation, so it was gradually developed and gradually replaced. N-type solar cells and to this day, when the demand for solar applications is more and more in civil and industrial power generation, P-Type cells with available advantages have gradually invaded and accounted for 80% of the total capacity. bridge.

In ground-based residential and industrial power generation applications, the N-type semiconductor has a superior performance advantage simply because it contains more charge carriers and less attenuation because of the absence of the boron- oxygen, a reaction that significantly degrades the performance of P-type panels when exposed to the sun

Nowadays, the production cost of N-Type Cells is getting cheaper and cheaper because the production technology of N-Type cells has become much more efficient and the increasing requirements for the efficiency and durability of solar panels make it easier to manufacture. Cell N-Type began to be produced more and more and in the future will replace P-Type.

ICB N-Type battery panels for the highest performance today.

The pinnacle in solar panel manufacturing technology today is the combination of IBC panel technology on N-Type panels. Sunpower and LG are two pioneers in Cell IBC N-Type monocrystalline silicon technology with 2 typical battery lines

- Sunpower : Maxeon series, maximum efficiency 22.7%

- LG: NeON R, maximum efficiency 21.7%

Although the production cost of IBC N-Type panels is expensive, in return, the panel efficiency is very high, the degradation over time is very low, providing high performance with good durability and stability, such as: Sunpower Maxeon battery panels commit to a 25-year to 92% performance warranty, up to 25-year product quality warranty.

Highlights of Sunpower’s IBC N-Type battery cell